In the world of RF (radio frequency) communications, selecting the correct RF connectors for your system is critical to ensuring optimal performance. Whether you’re designing a wireless network, a satellite communication system, or working with high-frequency test equipment, the right connector can make all the difference in maintaining signal integrity, minimising losses, and ensuring reliable communication. In this blog post, we will explore the key factors to consider when choosing RF connectors for your communication needs, while also highlighting Intelliconnect‘s extensive range of connectors designed for various applications.

What Are RF Connectors?

RF connectors are designed to join electrical circuits in RF systems, allowing signals to travel between components while minimising loss and distortion. They are essential in a wide range of communication applications, from broadband internet and television to satellite systems and wireless networks. Since RF signals are susceptible to interference, choosing the right connector is vital for ensuring efficient signal transmission.

Key Factors to Consider When Choosing RF Connectors

When selecting the right RF connector, several factors must be taken into account. Below are the most critical considerations for making the best choice for your system:

1. Frequency Range

The frequency range is one of the first factors to consider when selecting an RF connector. RF systems operate over a wide range of frequencies, from low frequencies used in audio equipment to high frequencies used in satellite communications and radar.

Each RF connector has a specified frequency range it can handle. If you choose a connector that is unsuitable for your application’s frequency, you risk poor performance, including signal degradation and potential system failure. For example:

- Low-frequency connectors (such as BNC or TNC) are suitable for frequencies up to several gigahertz.

- High-frequency connectors (such as SMA, N-type, and SMP) are designed to perform optimally in systems that operate at higher frequencies, often in the microwave and millimetre-wave ranges.

Intelliconnect offers a variety of connectors suited for both low- and high-frequency applications, including their SMA, N-type, and MMCX connectors that perform reliably across a broad frequency range. For higher-frequency requirements, they provide MMCX connectors, often used in compact, high-frequency systems like mobile communications.

2. Impedance Matching

Impedance matching is another key consideration for RF connectors. RF systems typically have a characteristic impedance of 50 ohms or 75 ohms, and it’s crucial that the connectors used match this impedance to avoid signal reflection, power loss, and interference.

- 50-ohm connectors are commonly used in general RF applications, including wireless communication and test equipment.

- 75-ohm connectors are typically used in video transmission, cable television, and some satellite communications.

Intelliconnect provides 50-ohm connectors that are ideal for standard RF systems, ensuring low signal loss and reflection in applications like networking, broadcast, and instrumentation.

3. Connector Type

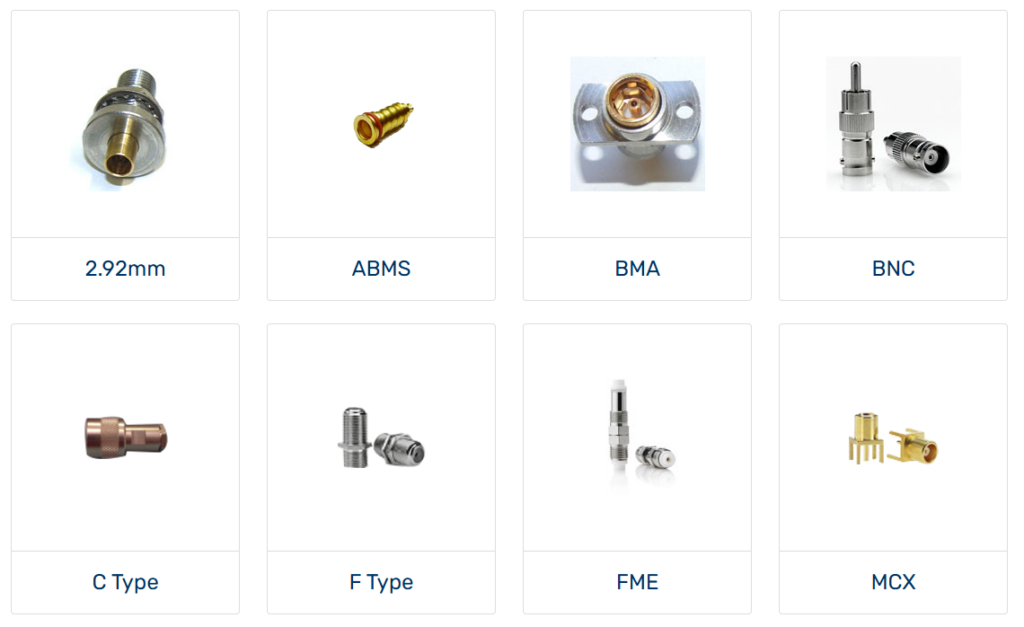

There are many different types of RF connectors, each with its own features and applications. Some common RF connector types include:

- SMA (Subminiature Version A): Popular for high-frequency applications (up to 18 GHz) in wireless communication systems, test equipment, and satellite systems. The SMA connector is compact, reliable, and has low signal loss. Intelliconnect offers a range of SMA connectors in both male and female versions, ideal for high-precision applications.

- BNC (Bayonet Neill-Concelman): Often used in lower-frequency systems (up to 4 GHz) and for video and test equipment applications. BNC connectors feature a bayonet coupling mechanism for easy installation and removal. Intelliconnect provides BNC connectors that offer secure, reliable connections for audio-visual and general test equipment.

- N-type: Known for their durability and performance in both low and high-frequency systems (up to 11 GHz). N-type connectors are commonly used in antenna systems, radio transmitters, and networking equipment. Intelliconnect offers a variety of N-type connectors with excellent performance in outdoor and rugged environments.

- TNC (Threaded Neill-Concelman): A threaded version of the BNC connector, offering improved performance at higher frequencies (up to 11 GHz). TNC connectors are often used in wireless communication and networking.

- F-type: Often used in consumer-grade cable television systems, F-type connectors provide reliable connections in low-frequency systems (up to 1 GHz). Intelliconnect offers a range of F-type connectors, perfect for applications in the entertainment and broadcast industries.

For those working with precision equipment, Intelliconnect offers connectors that ensure reliable performance across various frequency ranges and applications, from coaxial connectors to fibre-optic solutions.

4. Connector Size and Form Factor

The physical size and form factor of the RF connector are also important. RF connectors come in a variety of sizes to accommodate different cables, from small form factors like the SMA connector to larger connectors like the N-type.

The size and form factor must be compatible with the cable you are using, as well as the space available in your equipment. Compact connectors like SMA are ideal for tight spaces, while larger connectors such as N-type may be necessary when higher power handling is required.

Intelliconnect provides an extensive selection of connectors across various sizes and form factors, ensuring compatibility with your equipment and cable requirements. Their SMA, N-type, and MMCX connectors are available in a variety of configurations to accommodate a wide range of applications.

5. Durability and Environment

RF connectors must be able to withstand the physical and environmental conditions they will be exposed to, particularly in industrial or outdoor settings. Some of the factors to consider include:

- Weather Resistance: If your application is outdoors or in harsh environments, look for connectors that offer weatherproofing, such as those with waterproof seals or corrosion-resistant materials.

- Mechanical Durability: RF connectors that are subject to frequent mating and unmating cycles (like in test equipment) require robust, long-lasting designs, such as those with gold-plated contacts or secure locking mechanisms.

- Vibration and Shock Resistance: Applications in the aerospace or automotive industries require connectors that can withstand high levels of vibration and shock. In these cases, you’ll need to choose connectors that meet military or aerospace standards.

Intelliconnect offers highly durable connectors, such as their weatherproof and ruggedised connectors, designed to withstand challenging environments. Their products are widely used in applications like military communications, industrial automation, and aerospace systems.

6. Power Handling Capacity

Power handling is another consideration when selecting RF connectors. Depending on the application, the RF system may involve high-power signals, which demand connectors capable of handling large amounts of power without overheating or degrading.

For instance, connectors in satellite communication systems or broadcast applications may need to handle higher power levels, whereas connectors in test systems or low-power communications may have lower power handling needs. Be sure to select connectors that can reliably handle the power levels required by your system.

Intelliconnect’s high-power RF connectors are engineered to manage high-power systems without sacrificing signal quality. These connectors are suitable for use in both commercial and military-grade applications that demand high power handling.

How to Choose the Right RF Connector for Your Communication Needs

- Identify Your Application’s Frequency Range: Ensure that the RF connector supports the frequency range of your application. For high-frequency applications, connectors like SMA, N-type, or MMCX connectors from Intelliconnect are ideal.

- Check Impedance Compatibility: Make sure the connector’s impedance matches that of your system—50 ohms for general RF applications or 75 ohms for video and cable systems.

- Consider Durability Requirements: Assess the environmental and mechanical durability required by your system. Intelliconnect offers ruggedized connectors for outdoor and harsh environments.

- Choose the Right Connector Type and Size: Select the appropriate connector type based on frequency, power handling, and physical size, ensuring it fits your system’s design and application needs.

- Evaluate Performance Needs: Consider the importance of low signal loss, high power handling, and ease of use in your application to determine the best connector for the job.

Conclusion

Choosing the right RF connector is crucial for ensuring the performance, reliability, and efficiency of your communication systems. By understanding the key factors—frequency range, impedance, connector type, durability, and power handling—you can make an informed decision that will optimize your RF system’s operation. Whether you’re working in satellite communications, wireless networks, or high-frequency testing, selecting the correct connector is essential for seamless and effective RF signal transmission.

With a comprehensive selection of SMA, N-type, MMCX, and other RF connectors, Intelliconnect provides engineers and system designers with high-quality solutions to meet their RF connectivity needs, ensuring superior performance and long-term reliability.