In the world of radio frequency (RF) testing, having accurate and reliable test equipment is essential for characterising, troubleshooting, and developing high-frequency devices and systems. RF test equipment, such as signal generators, oscilloscopes, and spectrum analysers, is typically designed to operate within specific frequency ranges. However, as technology advances and applications demand higher frequencies, the need to extend the frequency range of test equipment becomes increasingly important.

This blog explores the methods, techniques, and considerations for extending the frequency range of RF test equipment, helping engineers and technicians push the limits of their testing capabilities and ensure the optimal performance of their high-frequency systems.

1. Why extend the frequency range of RF test equipment?

As wireless communication, satellite systems, radar, and other RF-based technologies evolve, there is a growing need to test and measure signals at frequencies beyond the capabilities of traditional RF test equipment. Key drivers for extending the frequency range include:

- Emerging Technologies: New applications in 5G/6G networks, IoT (Internet of Things), advanced radar systems, and aerospace technologies require testing up to tens of gigahertz (GHz) and even beyond 100 GHz.

- Component Development: As RF components, such as antennas, filters, and transistors, continue to operate at higher frequencies, ensuring their performance at these frequencies is crucial.

- Regulatory Compliance: With strict electromagnetic interference (EMI) and electromagnetic compatibility (EMC) regulations, testing equipment must be capable of measuring spurious emissions at higher frequencies to ensure compliance.

- Research and Development: Pushing the limits of frequency capabilities allows researchers to explore new frontiers in signal processing, communications, and material science.

2. Challenges of Extending the Frequency Range

Extending the frequency range of RF test equipment presents several technical challenges that engineers need to address:

- Signal Integrity: As frequencies increase, maintaining signal integrity becomes more challenging. Higher frequencies experience more attenuation, losses, and signal degradation in cables, connectors, and test fixtures.

- Component Limitations: Traditional RF components like mixers, amplifiers, and filters are designed for specific frequency ranges. Operating at higher frequencies requires components that can handle these signals with minimal distortion.

- Measurement Uncertainty: At higher frequencies, measurement uncertainty can increase due to factors such as noise, bandwidth limitations, and inaccuracies in calibration.

- Cost and Complexity: Test equipment capable of measuring signals at higher frequencies is often more expensive, both in terms of initial cost and maintenance. The complexity of the equipment also increases, requiring more advanced techniques and expertise to operate effectively.

3. Techniques for Extending the Frequency Range

To extend the frequency range of RF test equipment, several techniques and strategies can be employed. These range from using advanced technologies to implementing effective calibration and signal processing methods.

a. Use of Frequency Extension Modules and Upconverters

One of the most common ways to extend the frequency range of RF test equipment is by using frequency extension modules or upconverters. These devices effectively shift the frequency of the signal into a range that the test equipment can handle.

- Frequency Extension Modules: These are specialised hardware add-ons that increase the upper frequency limit of spectrum analysers, oscilloscopes, or signal generators. They use mixers or multipliers to shift the input signal to a higher frequency, allowing the test equipment to measure it accurately. For example, a spectrum analyser with a maximum frequency of 40 GHz can be paired with a frequency extension module that pushes it to 70 GHz or higher.

- Upconverters: An upconverter takes a lower frequency signal and converts it to a higher frequency, often used in test setups where signals need to be measured at a frequency above the equipment’s built-in capabilities. Upconverters are essential for extending the frequency range of signal generators and analysers in high-frequency applications.

b. Use of High-Frequency Components

To test higher frequencies, it is crucial to use RF components that are designed for high-frequency applications. This includes:

- Microwave Components: These components, such as amplifiers, mixers, and couplers, are specifically designed to handle frequencies in the microwave range (above 1 GHz). For frequencies beyond 40 GHz, millimeter-wave components are used, and they must be carefully selected to ensure minimal signal loss and distortion.

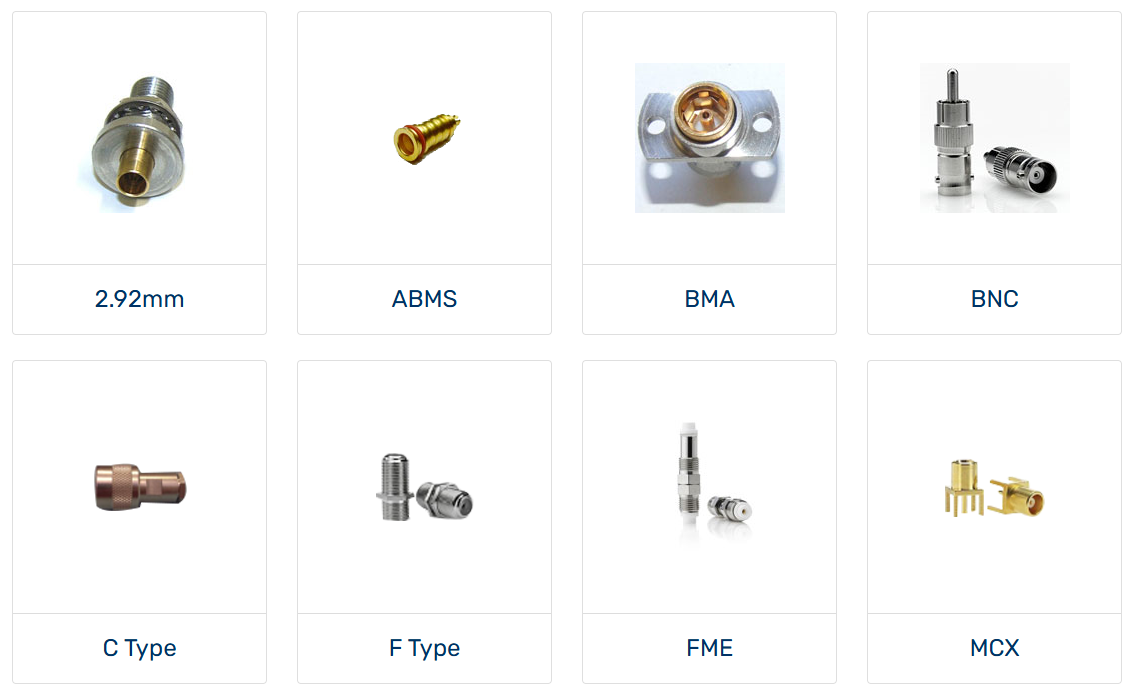

- Low-loss Cables and Connectors: At high frequencies, even small losses in cables, connectors, and adapters can significantly affect measurement accuracy. Using specialized microwave cables (e.g., semi-rigid coaxial cables) and high-frequency connectors (such as 2.92 mm, 2.4 mm, or 1.85 mm) can minimise signal degradation.

c. Digital Signal Processing (DSP) Techniques

Another approach to extending the frequency range involves leveraging digital signal processing (DSP) techniques. DSP allows the processing of high-frequency signals in the digital domain, enabling the extraction of relevant information without the need for direct measurement in the analog frequency range.

- Sampling at Higher Rates: Modern oscilloscopes and analyzers can use high-speed sampling techniques to digitize signals at very high frequencies. By sampling the signal at a rate greater than twice the signal frequency (known as the Nyquist rate), it’s possible to capture the characteristics of the signal and process it digitally.

- Interpolation and Decimation: Once a signal is sampled, DSP algorithms can interpolate (increase the frequency resolution) or decimate (reduce the data rate) to extend the measurement capabilities of the equipment.

d. Use of Wavelength-Scaling Techniques

Wavelength-scaling techniques involve scaling the wavelength of the test signal to match the test equipment’s frequency range. These techniques are especially useful in applications where high-frequency signals are difficult to generate directly but can be represented at lower frequencies using mathematical models or signal scaling.

For instance, in some high-frequency radar and communication systems, engineers may use modulation techniques to shift the signal into a lower frequency range that test equipment can measure more easily.

e. Utilizing Software Defined Radio (SDR) Systems

Software-defined radios (SDRs) are increasingly used in high-frequency testing. SDRs use software for signal generation, processing, and analysis, allowing for greater flexibility in handling a wide range of frequencies.

- Frequency Flexibility: SDRs can tune to different frequency bands without the need for hardware modifications, making them ideal for environments where the frequency range needs to be adjusted frequently or dynamically.

- Signal Analysis Capabilities: Advanced signal processing algorithms in SDR systems allow for real-time analysis and visualisation of complex high-frequency signals, which is crucial for developing and testing next-generation RF systems.

4. Considerations When Extending Frequency Range

While extending the frequency range of RF test equipment is crucial for meeting modern testing requirements, engineers must consider several factors:

- Accuracy and Calibration: When extending the frequency range, it is vital to recalibrate test equipment and verify measurement accuracy at higher frequencies. Calibration kits designed for higher frequencies must be used to maintain reliable results.

- Signal Integrity: As frequencies increase, it becomes harder to maintain signal integrity. Engineers should account for signal attenuation, noise, and distortion that may affect the quality of measurements.

- Cost and Budget: High-frequency testing equipment can be costly. Engineers must weigh the costs of upgrading equipment or investing in external modules (such as frequency extension kits) against the benefits of more accurate high-frequency testing.

- Compatibility: Ensure that the test equipment, adapters, cables, and other components are compatible with the extended frequency range to avoid mismatches and measurement errors.

5. Conclusion

Extending the frequency range of RF test equipment is crucial for testing and characterising the performance of modern RF systems that operate at higher frequencies. By employing techniques such as frequency extension modules, using high-frequency components, leveraging digital signal processing, and utilising software-defined radios, engineers can significantly increase the capabilities of their test equipment and meet the demands of advanced technologies.

However, the process of extending the frequency range comes with its challenges, including signal integrity, calibration, and cost considerations. With careful planning, accurate calibration, and appropriate component selection, engineers can ensure that their test equipment remains relevant and effective in the face of ever-increasing frequency demands in the RF and microwave domains.